Carpet Printing Technologies

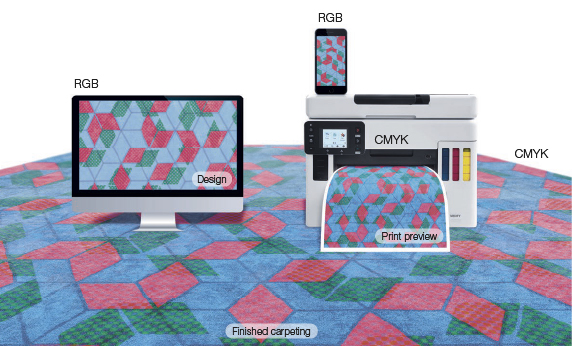

Your desired design usually starts on the computer and continues through the production of a printing pattern, based on which the final carpet pattern is subsequently created.

Color System/Scheme

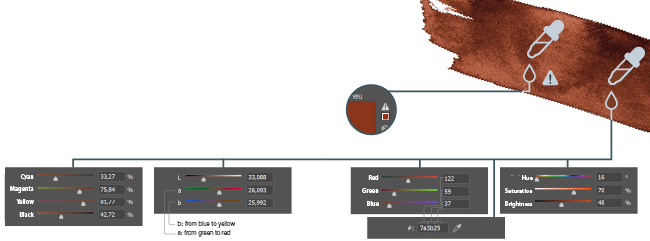

A color system is an approach or method for organizing colors. Known color systems include color wheels, color catalogs, color atlases, or color models. Color models are special color systems that are often mathematically defined by a coordinate system and derive from several defined primary colors.

Color Space

A color model contains a three-dimensional color space (e.g., Adobe-RGB as the color space of the RGB model). Within the color space, each color has precise color coordinates, which are usually defined by three coordinates.

The Lab* space corresponds to the zone perceivable by the human eye and is therefore the target zone. The RGB space (e.g., monitor) as well as the CMYK space (e.g., printer) are only subsets of the Lab* space. Both RGB and CMYK spaces have their limitations, which is why not every color in the Lab* space can be displayed in other color spaces - this is a common cause of discrepancies between colors on the monitor and colors on the carpet.

Gamut

Gamut designates the entire range of colors that a device can display or reproduce. The device-specific gamut is directly related to the technology used. For example, a certain monitor can reproduce a different color gamut than a mobile phone, although both work according to RGB principles with light color mixtures, and a device like an inkjet printer (CMYK principle) functions differently. The gamut - unlike the color space - is variable. An old, worn, or technically damaged machine can affect the result just as much as using new inks.

Color Profile

The gamuts of two devices always differ, sometimes significantly. Color profiles therefore enable the "transfer" from monitor (RGB) to printer (CMYK) without significant color shifts. They are a kind of translation or conversion tools between two devices that aim to maximize the approximation of the visual printing result to its digital original. Color profiles also take into account the medium to be printed on, i.e., the type of paper or in the case of carpet printing - the type of yarn.

Types of Carpet Printing Technologies

The system works with two printing techniques that do not differ in the preparation and processing of goods:

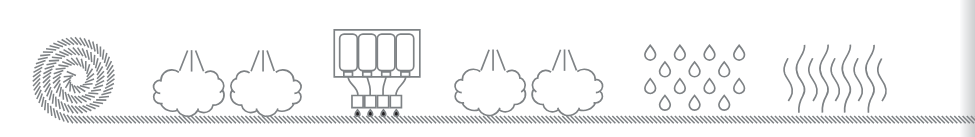

1. Feed of selected quality: The desired carpet quality is inserted into the printing line and prepared for printing.

2. Steam fixation: The raw material is exposed to steam immediately before the final carpet printing.

For the printing process, there are two types of machines to choose from:

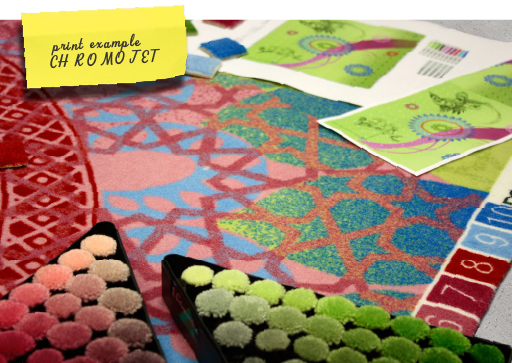

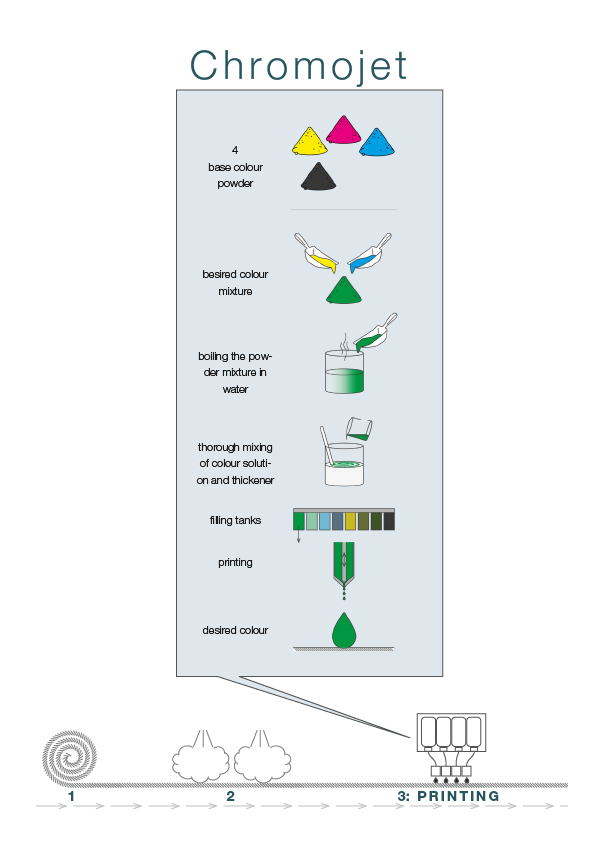

3. a) Printing with Chromojet: With the third generation Chromojet, up to 24 color pastes can be set. Individual colors must first be weighed and mixed before being dissolved in hot water, cooked, and added to the already prepared thickener. After thorough mixing, the color pastes can be filled into the color tanks. The carriage apparatus with printing nozzles applies the color paste in precise drops according to the design to be printed. After each printing cycle, the product moves one step further until all rows are printed.

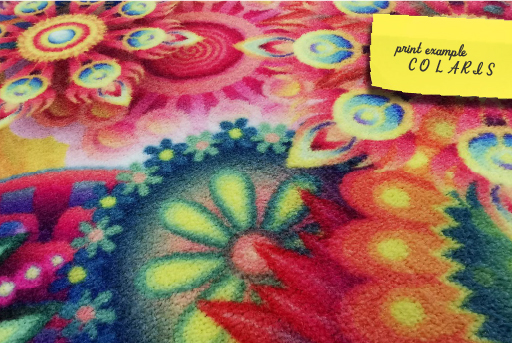

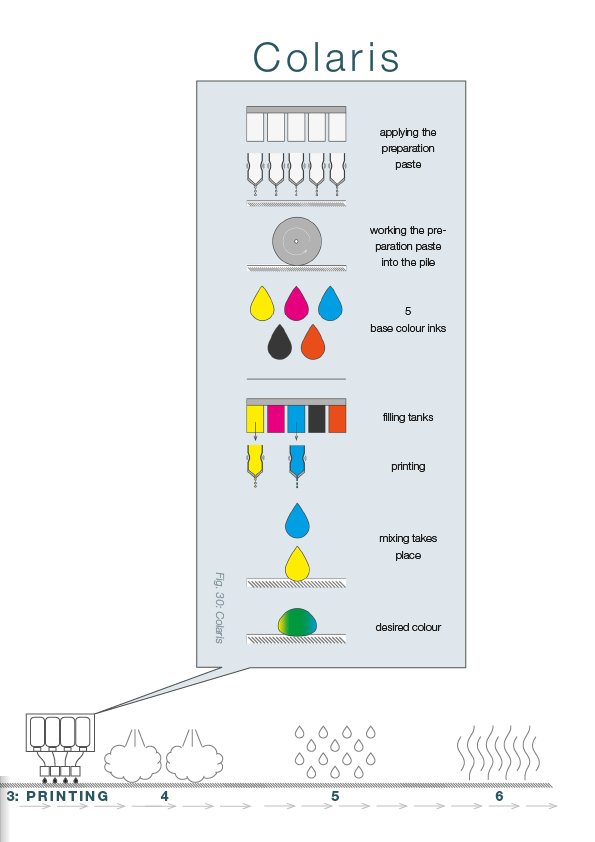

3. b) Printing with Colaris: Colaris eliminates the need to pre-mix color pastes. This is because liquid colors are used here, which - based on the principle of the home inkjet printer - are only mixed into final color shades on the fabric. This enables almost unlimited color variety. Since liquid colors are thinner than pastes, an additional work step is required - the application of preparatory paste, which adapts to the requirements of the yarn. When this is completed and the material is pre-prepared, the actual printing process begins. Colaris works with a rotating print head and piezo technology, where color drops are created by expansion and contraction of piezo crystals. Complex computer calculations are needed to generate optimal drop size and quality for the corresponding carpet type and selected graphics.

4. Steam fixation: The carpet is steamed again to fix the colors.

5. Washing: The washing cycle removes excess color and preparatory paste.

6. Drying: Finally, the wet carpet fabric is dried. This completes the printing process.

What influences the printing result?

- graphic design

- color selection

- gamut mapping

Graphic design - Your design intended for carpet printing should meet the following conditions: → file dimensions corresponding to carpet dimensions (1:1) → resolution of at least 100 dpi → for text and simple patterns: vector format is preferred → for photorealistic motifs with color preferences (e.g., special colors)

Desired color according to sample:

Only if your colors do not match the sample exactly, colorimetric measurement is necessary. This can be fabric, carpet, color card, or template that is placed in the camera system and the areas to be measured are defined. The spectral coordinates and measured color coordinates Lab* values are the output for each color.

Printing preparation

Mixing color pastes (Chromojet only): First, a recipe is created that specifies individual colors, starting material, and all other parameters. Mixing color pastes requires attention to specified viscosity values. When mixing color pastes, it is important to pay attention to the correct viscosity, which often has a positive effect on the final printing result.

Different yarn types require different color recipes that must be created individually. Therefore, it is not possible to simply print the selected design on the second or third yarn type using the same color pastes. The same design, same colors, but different yarn means a completely new work procedure.

Laboratory printing: The finished color pastes are used to fill the tanks of the Chromojet laboratory printing system. With Colaris, colors are always applied in standard mode. The selected yarn quality is dried before starting and printed with the desired design. This creates a "manual pre-production sample" that still needs additional processing.

Additional processing: After laboratory production, the manual sample is sterilized, washed, dried, and then steamed again so that the colors reach their final state and the sample can be visually assessed.

Control and approval: The pre-production sample must now be re-evaluated regarding the specified colors and overall impression. In case of deviations, a new print is created under standardized daylight D65 until it reaches the required parameters for approval, after which the pre-production sample is sent to the customer.

After approval of the pre-production sample by the customer, production can begin.

Manual sample evaluation

WHAT CONDITIONS ARE RECOMMENDED?

LIGHT SOURCE - We evaluate under standardized daylight D65. Commercial light or UV light can also be used if necessary.

The manual sample should be evaluated under a light source similar to the light used during sampling. Other lighting conditions (e.g., evening light) and mixed lighting situations (e.g., daylight and artificial light) are misleading and should therefore be avoided.

CARPET - The quality of the carpet being printed also determines the color effect. For example, shiny yarn reflects its surroundings much more strongly, which usually mixes with the design color.

Different carpet qualities look different despite the same printing. This should be taken into account when ordering or reordering.

The yarn direction also affects the color effect. If carpet pieces are to be compared, they must be placed in the same direction and observed from above, in the yarn direction.

EYES - The manual sample is more than the sum of printed color dots. Only in combination with the design does a cohesive overall image emerge for the observer. The overall impression is therefore decisive.

Before shipping, the sample is approved by a small group of designers in our premises. This means that individual visual preferences or habits can be balanced among each other.

Print quality recognition

WHAT CHARACTERISTICS ARE EVALUATED?

Penetration

Penetration designates how deeply the printing paste penetrates into the yarn. If penetration is insufficient, the "heel" of the yarn remains white. If penetration is ideal, the yarn is colored up to about 90%, i.e., just before the tufted base.

If cut edges are not visible and the carpet to be tested cannot be creased, the yarn can be manually spread apart so that a magnifying glass can be used to assess penetration.

Sharp contour

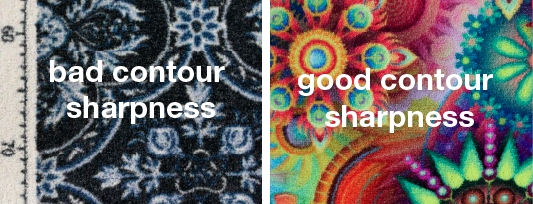

Although sharp contour is already a challenge with certain adjacent color areas (e.g., blue next to yellow without mixing green), fine lines on twisted yarns are the highest discipline. This requires knowledge of the behavior of printing pastes (e.g., tendency to "bleed"). The design must also be adapted to the properties of these pastes to achieve clearly defined, continuous lines in the desired width.

To evaluate sharp contour, areas with letters, hatching and fine contours, as well as transition areas of surfaces are carefully examined. Are individual colors clearly demarcated, is the line not "blurred" and not disproportionately wide or narrow?

Color purity

Colors should look clean and unclouded. Especially color tones that appear "hazy" or "milky" must be eliminated during production. This is where the interplay of color paste, printing parameters, additional processing, and know-how sharing is required.

The carpet can be evaluated using the following characteristics: Are the lightest tones bright and luminous enough or do they appear gloomy? Are the blackest/darkest areas dark enough or too pale? Do the colors between them have harmonious spacing and are they saturated according to requirements? Is the overall impression harmonious?

Explore material types: HERE: