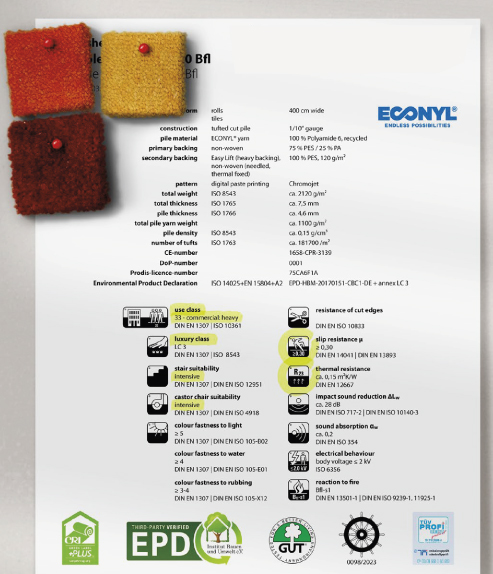

Carpet Specifications: Your Guide to Quality - Part One

Why are technical data important?

The world of carpets is full of technical specifications, certificates and tests. Our guide helps you understand all the important parameters that determine the quality and suitability of a carpet for your needs.

A carpet datasheet contains a wealth of important information about the specific product and its suitability for use. To properly interpret, compare and use this information in your purchasing decision, you need a basic understanding of all terms and relationships.

This guide serves as a reference manual and also provides insights into the procedures and processes of testing laboratories. Follow us and learn everything you ever wanted to know about technical datasheets for carpets.

Carpet Dimensions

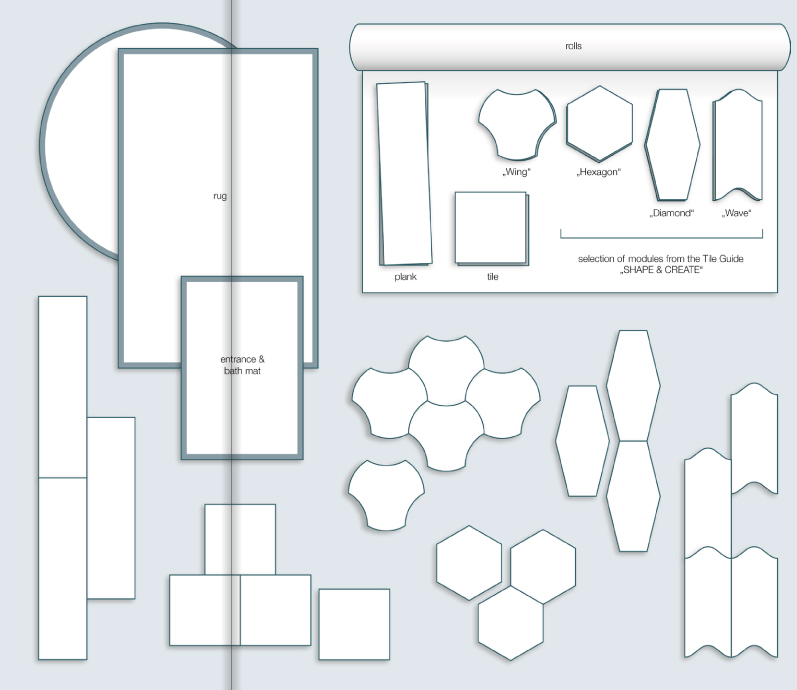

The delivery form determines in what format the carpet is delivered to the customer.

Carpet Rolls

A carpet roll has a specified maximum width but can be manufactured in practically unlimited lengths. For practical reasons, it is often cut directly to room dimensions. Rolls are usually bonded full-surface to the substrate.

Carpet Tiles

Tiles are carpet pieces cut from rolls in various shapes and sizes. A square is called a tile, a rectangular long shape is a plank. Carpet tiles can be freely combined, are easy to transport thanks to compact dimensions, and individual tiles can be easily replaced when damaged or soiled. Tiles do not necessarily need to be bonded to the substrate.

Finished Rugs and Mats

Rugs are manufactured in various sizes and shapes, most commonly rectangular. They have finished edge treatments, so they can be laid freely on the floor without bonding. Therefore, loose-laid rugs must meet less stringent requirements than full-surface carpets. The same applies to entrance mats and bathroom rugs.

Carpet Construction

Construction describes the technical manufacturing process of the carpet or rug. Carpets are usually manufactured using tufting, weaving or knotting techniques.

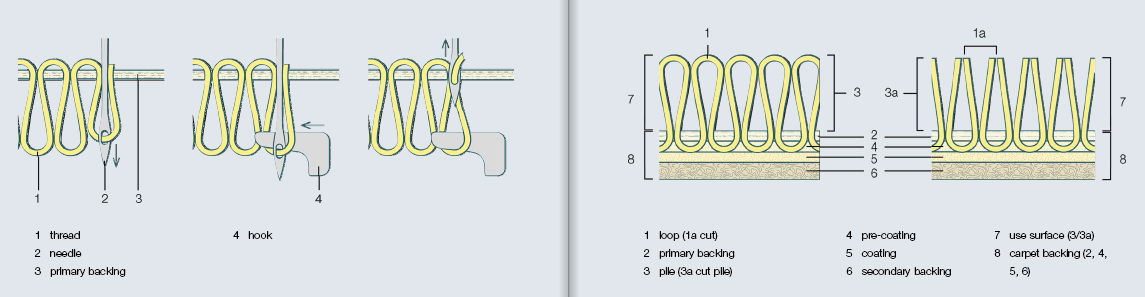

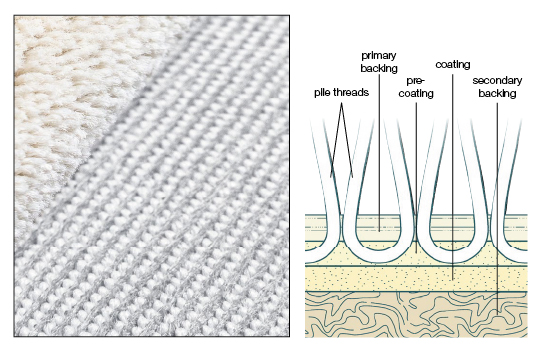

Tufting

Tufting is a technique for creating three-dimensional textile surfaces, where yarn is pierced with a needle from behind into a carrier backing and when withdrawing the needle it is caught with a hook, so it protrudes on the front side as a loop. Many dense rows of these pile loops form the pile or pile layer. If the loop heads are cut off, cut pile is created.

If a carpet is to be made from tufted material, a pre-impregnation must be applied to the back of the carrier backing for pile fixation. Impregnation and secondary backing complete the base layer of the carpet.

Tufted Loop Pile

A tufted quality whose pile loops are not cut is called tufted loop pile. The appearance resembles conventional terry towels - these also have uncut, small loops - although the manufacturing process is different.

Tufted Cut Pile

Tufted cut pile is tufted material with open yarn ends on the front side, which is made from loop material by cutting off the loop heads. The appearance of tufted cut pile without heat treatment is comparable to velvet, while thermofixed or chemofixed yarns form a granular surface. For laypeople, machine-tufted cut pile is difficult to distinguish from hand-knotted carpets.

Tufted = Sewn

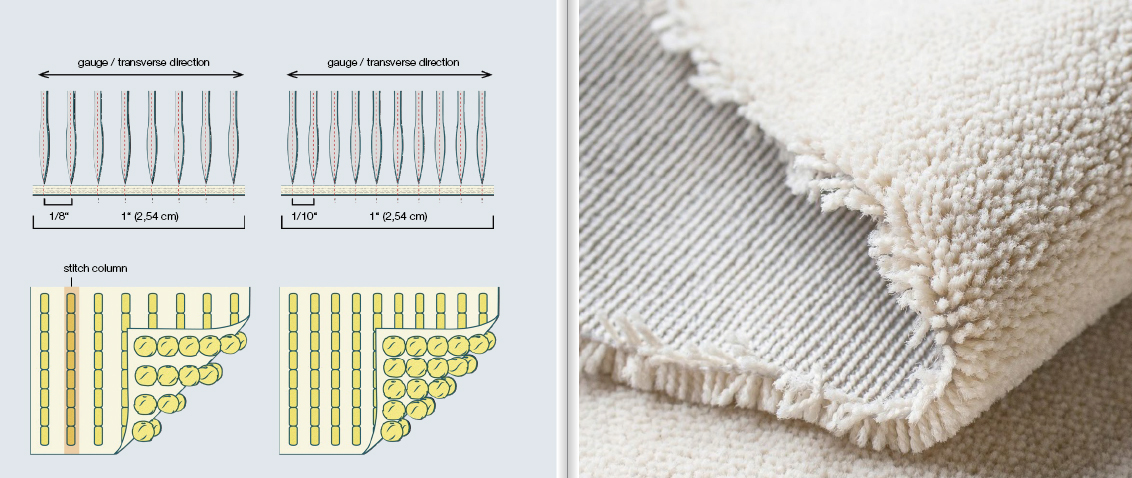

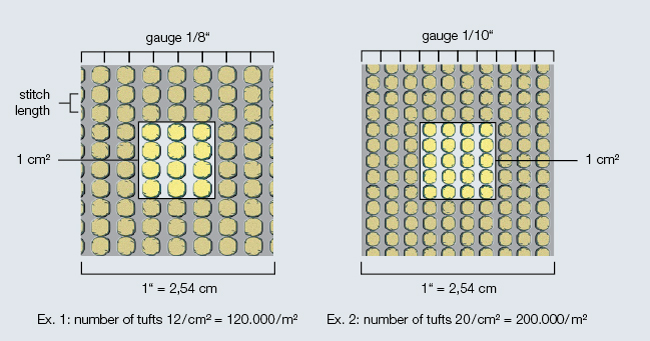

Needle Spacing (Gauge)

Needle spacing provides information about the distances between needles or pile loops and thus also about their number per inch/cm. For example, a product with needle spacing 1/8" has 8 stitch columns over the distance of 1 inch (2.54 cm) in the cross direction of the tufted material, while a product with needle spacing 1/10" has 10 stitch columns over the same distance. The stitch density in the longitudinal direction cannot be determined from this value (but can be calculated from tuft count and needle spacing, if necessary).

Pile Material

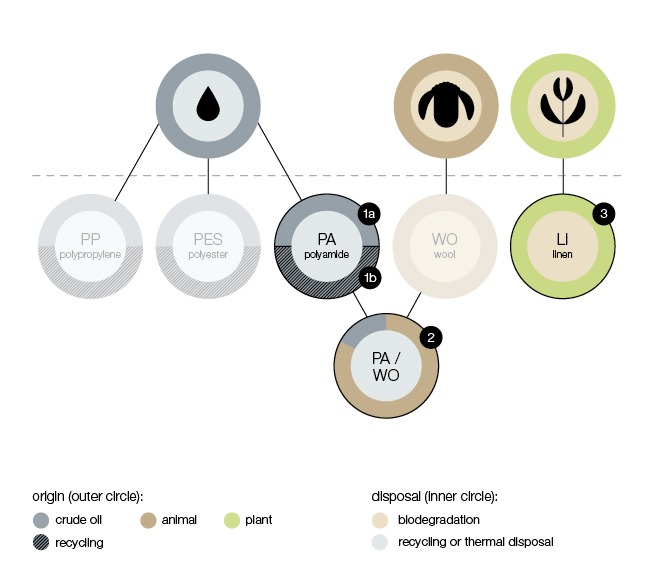

The material from which the yarn for the pile filaments is made is called pile material. This must be clearly marked with prescribed formulations according to textile labeling law. The most common pile materials for carpets and rugs are polypropylene (PP), polyester (PES), polyamide (PA) and wool (WO).

Polyamide is most commonly used mainly because it is the most durable fiber. However, natural fibers such as wool mixed with polyamide and pure linen (LI) are also processed. If recycled polyamide is used, this cannot initially be recognized from the material designation "PA" alone, as it is chemically identical to first-class qualities. However, it is then always marked as recycled yarn by both the yarn manufacturer and the carpet manufacturer.

Primary Backing

The primary backing is the textile base layer into which the pile filaments are inserted. It can be woven or non-woven material and can consist of either pure material or a mixture of materials.

Secondary Backing

The secondary backing is part of the base layer of the carpet along with pre-impregnation and impregnation. The secondary backing has direct contact with the floor. It can be woven material or non-woven textiles such as fleece or felt and fulfills various technical functions, particularly having acoustic and thermal insulation effects.

Due to the wide range of requirements and applications, both woven and non-woven textiles of various thicknesses, densities and compositions are used as secondary backing. The customer thus receives not only the desired surface but also fulfillment of their functional suitability profile on the back of the carpet or rug.

Non-woven Textiles

Non-woven textiles are flat materials consisting of individual, unordered fibers. There are non-woven textiles whose fiber bonding is achieved exclusively mechanically (e.g. needle-punched non-wovens, water-entangled non-wovens), those that are bonded under the influence of heat (e.g. thermally bonded non-wovens) and - more rarely - non-woven textiles that are bonded using adhesive.

Non-woven textiles are used as primary backings because they are more dimensionally stable than woven fabrics. They usually consist of a mixture of 75% polyester (PES) and 25% polyamide (PA).

For secondary backing, non-woven textiles are used in weights for example 120g/m², 280g/m², 550g/m², 600g/m² and 1000g/m². All non-woven textiles are stitched and - except for the quality of some exceptions - additionally thermally consolidated, resulting in a denser, firmer structure. Non-woven textiles 120g secondary backing are used in combination with thick impregnation "Easy-Lift" (EL), mainly for carpet tiles. For large tiles (e.g. 1.92m x 1.92m), the 1000g quality is generally used in connection with "Easy-Lift". Non-woven secondary backings consist of 100% polyester (PES), which comes from recycled PET bottles. Additionally, a variant made from viscose (VI) is also available.

Woven Fabrics

A woven fabric is a two-dimensional structure of threads that are usually arranged perpendicular to each other and interwoven according to a specific weave pattern.

Woven primary backing is used only for linen carpets and linen rugs of the LIN series. This woven fabric is also made from linen and is even compostable as part of the LIN Komp product.

For a long time, the entire carpet industry used only polyester fabric as secondary backing to give the tufted base carpet additional strength and dimensional stability. This polyester fabric is still chosen as secondary backing in more than half of all cases. For linen carpets LIN and LIN Komp, biodegradable jute fabric is used as secondary backing.

Pattern and Design

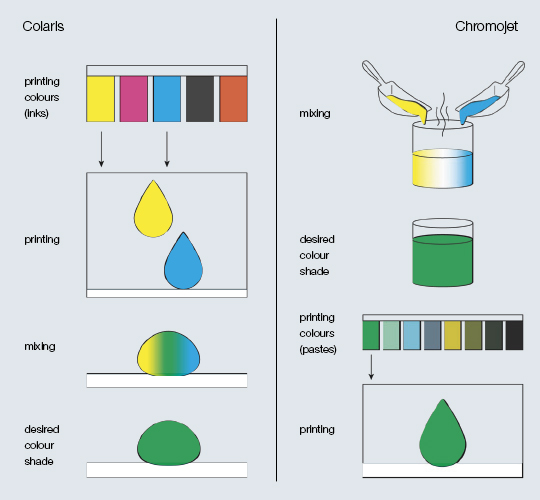

Pattern design can be achieved in carpet manufacturing through various processes.

Pattern design is usually created by printing on tufted, white base material, with a choice of two processes: On the Colaris printing machine, several basic color inks are used from which all other colors can be mixed in the process (process colors). On the Chromojet printing machine, a selection of pre-mixed color pastes is used (spot colors).

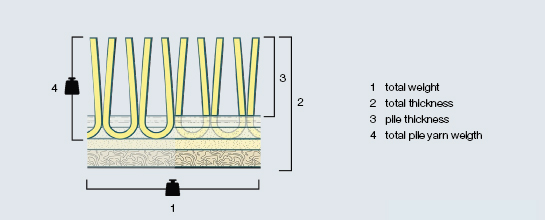

Total Weight

Total weight indicates how much one square meter of carpet or rug weighs including all layers.

Total Thickness

Total thickness indicates how thick the carpet or rug is including all layers.

Pile Thickness

Pile thickness indicates the height of visible filaments protruding from the primary backing above ground. The part embedded in the carpet or rug is not measured.

Total Weight of Pile Yarn

Pile weight indicates how much yarn material was used for pile production per square meter, i.e. how much is above, within and below the primary backing. This value can no longer be measured after completion of the carpet or rug, but can only be determined approximately by calculation.

Pile Density

Pile thickness alone doesn't tell the whole story, nor does the total weight of pile yarn. A carpet can be high but doesn't necessarily have to weigh much if it's only sparsely tufted. In professional jargon, this is referred to as "bulky" because the carpet looks rich, but its durability doesn't allow use in commercial spaces. Only the combination of pile thickness and total weight of pile yarn provides reliable information about the quality of the carpet or rug. In this context, the term "pile density" is used. It provides information about how much pile material is located in a specific area of the carpet above the primary backing. Higher pile density leads to the conclusion that overall performance characteristics improve and especially that acoustic effectiveness is better.

Tuft Count

Tuft count indicates how many loops are located on one square meter of flooring. As a tuft, either a pile loop or two ends of a pile filament are counted on the front side, while on the back side each stitch (piece of yarn between two insertion points) is counted. Tuft count is determined not only by needle spacing, but also by stitch length and thus the distance between tufts in the longitudinal direction. A high value in the technical datasheet is easier to understand if you first look at the tuft count per square centimeter and then convert to square meter.

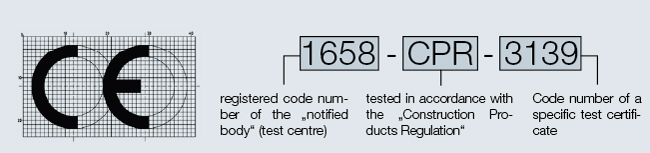

CE Number

CE marking indicates that the product has "conformité européenne" (European conformity), i.e. that all requirements placed on this product by the EU have been met. CE marking can be presented more or less detailed, but always contains the standardized CE marking.

CE marking can be read as follows: The first 4 digits of the CE number designate the "notified body" (testing center) that issued the CE marking. The assignment can be looked up in the relevant register. The letters "CPR" indicate that the product was tested in accordance with the "Construction Products Regulation". The last digits refer to the specific test certificate.

DoP Number

The term DoP means "Declaration of Performance". It confirms consistent quality (through continuous monitoring) of approved products and is required in addition to the CE number to obtain the relevant declaration of performance.

Prodis License Number

The association "Gemeinschaft umweltfreundlicher Teppichboden e.V." (GUT) has been advocating for environmental standards in the textile flooring industry since 1990. The eight-digit Prodis license number consisting of letters and digits must be entered on the GUT-Prodis website to gain access to the product passport of the relevant product. Alternatively, the QR code of the GUT-Prodis label can also be scanned. The product passport contains all information from the technical datasheet as well as more detailed information about the materials used and their environmental compatibility. However, it is only available online, not as PDF.

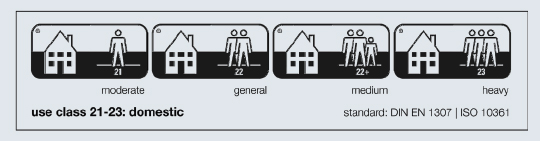

Usage Classes

The usage class provides information about the application area (private or commercial) and usage intensity (light to very heavy) for which the carpet flooring is suitable.

Usage classes 21-23 characterize the suitability of carpet floorings for residential use. Class 21 means light traffic, 22 general traffic, 22+ medium traffic (if existing) and 23 heavy traffic.

Residential areas can be for example: bedrooms, guest rooms, hobby rooms, home offices, living rooms and children's rooms, kitchens, bathrooms, hallways, entrance areas etc.

Usage classes 31-33 characterize the suitability of carpet floorings for commercial use. Class 31 means light traffic, 32 general traffic and 33 heavy traffic.

Commercial areas can be for example: hotel lobbies, corridors and rooms, open-plan offices, waiting areas, classrooms, shops and department stores, airports etc.

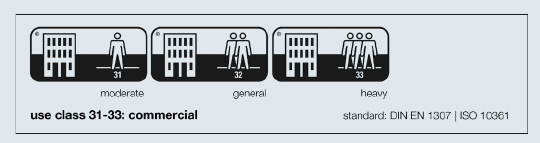

Luxury Class

The luxury class of carpet flooring is based on the weight per unit area of its wear layer. One crown corresponds to the lowest luxury class (LC1), five means highest comfort (LC5). The luxury class also allows assignment of impact sound reduction to the corresponding total weight without measurement. Thus a carpet of class LC1 absorbs more than 10 dB, one of class LC2 more than 20 dB and a carpet of class LC3 more than 25 dB of the generated impact sound.

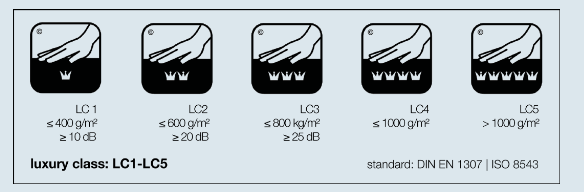

Stair Suitability

If the flooring is suitable for occasional use on stairs, the carpet is sufficiently abrasion-resistant at stair edges under light use. Recommended only for residential areas. If the flooring has intensive stair suitability, it is also sufficiently abrasion-resistant at stair edges under high and permanent use and is suitable for installation in commercial areas.

Castor Chair Suitability

If the carpet flooring has a castor chair suitability rating "occasional", it is usable under light stress from office chair castors. Recommended only for residential use. If the flooring has a castor chair suitability rating "intensive", it is also usable under high and permanent stress from chair castors and is also suitable for installation in commercial areas.

COLOR FASTNESS

Light Fastness

A carpet flooring is light-fast if it is color-stable when exposed to daylight. The color result is evaluated with a value between 1 (= very low) and 8 (= excellent). From test score 5, the flooring is suitable for commercial use.

Water Fastness

A flooring has water fastness if it loses no color and also doesn't stain anything else. Water resistance is judged with a value between 1 (= very low) and 5 (= excellent). From test scores ≥ 4 for bleeding and ≥ 2-3 for staining, the carpet flooring is suitable for commercial use.

Color Fastness to Mechanical Stress

A carpet flooring has color fastness to mechanical stress if it loses no color or stains other fabrics when exposed to mechanical stress in dry or wet conditions. Resistance to dry and wet rubbing is judged with a value between 1 (= very low) and 5 (= excellent). From test results ≥ 3-4 for dry rub resistance and ≥ 3 for wet rub resistance, the flooring can be used in commercial areas.

All color fastnesses (to light, to water, to rubbing) are judged using standardized contrast scales, gray or blue scales. These are explained at the beginning of the "test procedures" section.

Edge Stability

If the flooring has high edge stability, it remains attractive at cut edges during installation and use, i.e. the backing doesn't separate, doesn't lose loops and doesn't fray. This property is especially important when the carpet is used for tiles.

Slip-Resistant Properties

Slip-resistant properties are guaranteed if the flooring has a dynamic friction coefficient ≥ 0.3 in dry and wet conditions, i.e. sufficient adhesion on the flooring for the user to prevent slipping. The new symbol additionally contains the friction coefficient as a numerical value.

Carpet always meets this requirement.

Thermal Resistance

The symbol indicates that the measured thermal resistance value of the carpet was determined at room temperature 23°C. Thermal resistance expresses how well a material can resist heat transfer (low thermal resistance = fast heat transfer, high thermal resistance = slow heat transfer). If thermal resistance is ≤ 0.17 m²K/W, it can be assumed that the flooring doesn't significantly impede heat distribution from underfloor heating. In this case, the older symbol with the designation underfloor heating suitability may still appear.

ACOUSTICS

No other flooring has such a favorable influence on room acoustics as carpet! While hard floors reflect sound waves (echo in the room) or transmit them through the substrate and building construction (you hear the neighbor's footsteps), even an ordinary carpet absorbs more sound than, for example, laminate flooring with insulation underlay. This positively affects both damping (reduction of volume and echo in the room) and isolation (limitation of sound transmission to adjacent rooms). This can be optimized through proper design of carpet and substrate. This way, not only the noise level (dB) can be reduced, but also the frequency range (Hz) can be influenced.

We are happy to provide you with more information on this topic during personal consultation or in our "Acoustics" overview.

ELECTRICAL PROPERTIES

When walking on the floor in shoes with soles or through friction of clothing when sitting, materials can become electrostatically charged. The subsequent discharge in the form of a weak electric shock (e.g. when touching a door handle or car body) can be unpleasant but also dangerous for people and sensitive electronic devices, or can trigger unwanted chemical reactions. To prevent exceeding a dangerous charge level, special floor solutions are used - antistatic, dissipative or conductive coverings (sometimes also carpets). They are used for example:

- in operating rooms and intensive care

- in laboratories

- in server rooms

- in industrial manufacturing of sensitive components

- when processing fuels and solvents

- in manufacturing flammable or explosive dusts, gases and compounds

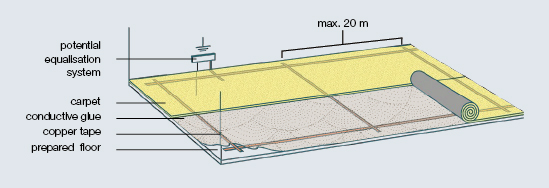

A distinction is made between conductive and dissipative floor coverings according to their surface resistance. Requirements for floor grounding can be found in installation recommendations and depend on the specific installation. If the carpet needs to be grounded, this must be performed by a specialist. For this purpose, it is usually bonded to a copper mesh using conductive adhesive and connected to the equipotential bonding system provided by an electrician. There are also other grounding systems; decisive is the functionality of the entire construction and compliance with applicable standards.

Antistatic

A flooring is considered antistatic if the measured body voltage of a person walking on it is below 2 kV.

Electrostatic Discharge (ESD)

If the measured through-resistance of the floor to current flow is ≤ 10⁹ Ω (1,000,000,000 Ω), it is considered electrically dissipative. In this case, connection to the equipotential bonding system is recommended. Dissipative floor coverings are suitable for rooms with electronic equipment such as data centers.

If the measured through-resistance of the floor to current flow is ≤ 10⁶ Ω (1,000,000 Ω), it is considered electrically conductive and conducts voltage even faster. Such a solution requires connection to the equipotential bonding system. Conductive floor coverings are used for example in rooms with unprotected electronics, explosive materials, in laboratories and healthcare facilities.

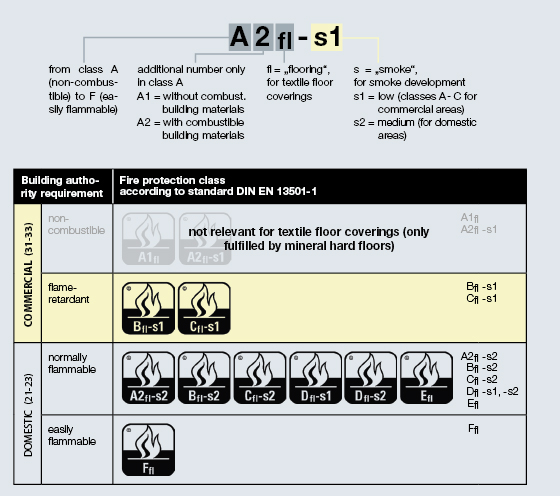

FIRE BEHAVIOR

Floor coverings used in commercial buildings belong to construction products and therefore are subject to the Construction Products Regulation, which defines fire behavior classes. Classes A1fl and A2fl-s1 (non-combustible) refer only to mineral hard floors, while the highest possible classes for textile floor coverings are Bfl-s1 and Cfl-s1 (flame retardant), which allow their installation in commercial areas.